Unparalleled Control

over your cooling

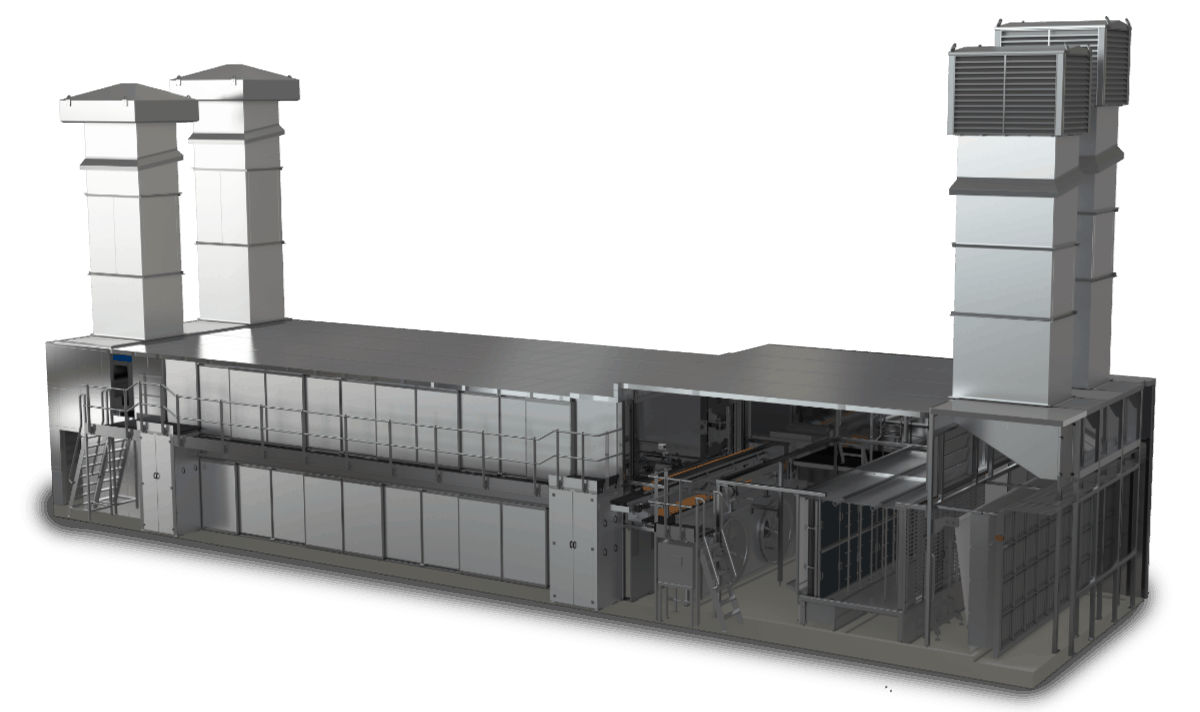

Designed to ensure an excellent finished product, Spooner industrial bakery coolers provide the desired core temperature to cool products without loss of quality.

Our industrial coolers are easy to use, control and are designed to fit into any existing product line or space.

Not just bread...

We’ve made coolers for a range of products including……..

What cooler type works best for each product?

We continually improve our range of coolers – using our knowledge we ensure the best product quality

Spooner range of coolers

Tunnel cooler

Spiral cooler

Conditioning systems

Drives

Loaders and unloaders

Product tracking

Designed For You

After years of experience Spooner know that plant space can sometimes be an issue, that’s why we tailor solutions exactly to our customers’ needs. We have designed coolers of all shapes and sizes.

Not only do we work with our customers to ensure our designs fit their requirements we also work with them to ensure the product quality is excellent, including process research and development in our R and D centre.

Supplying globally we provide bespoke cooler solutions as well as provers, ovens and heat recovery systems to food plants far and wide.

Typical Technical Specifications

All our coolers are highly configurable to your specific needs, generally they are available within the following parameters.

Feature | Typical Specifications |

|---|---|

Width Range | Up to 5m on Rack Up to 4m on Tunnel |

Length | Depended on type and product |

Temperature | Nominally 10 – 20c |

Configuration | Rack, Tunnel or Static |

Cooling Method | Evaporative or Refrigerated |

Humidity Source | High or low pressure water spray |